Alltorc Information

Behind all torc companies is a unique, patented, low melt re-usable thermoplastic

FlexiWrap

FlexiTorc

Key to the process is an innovative patented thermoplastics compound that has the property to be thermally moulded at a temperature comfortable for skin contact, but which is a semi-rigid rubber-like solid at body temperatures.

torcTuff

torcShield

Developing mouldable protective wear utilising the unique properties of the torc material within a composite structure using lightweight wearable technology that can be shaped directly onto the skin without harm and offers users a cost effective lightweight protective second-skin.

torc2

torc2 Material

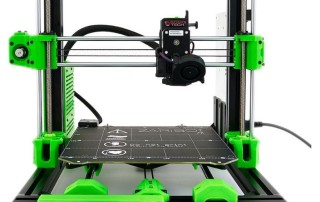

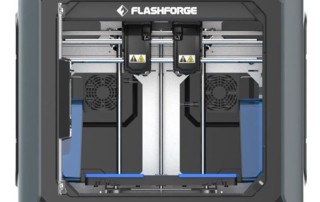

The material property when applied to splint and cast production by the latest techniques of additive layer manufacturing allows for the creation of patient specific products via a rapid methodology offering real benefits in delivery time, accuracy, comfort and ease of adjustment.

torcProtective

STFC

UKRI Science Technology Facilities Centre

Our Supporters

From the start of the torc journey we have been given invaluable support from the following

Dr Zuoxin Zhou, Research Fellow, Engineering Materials

“I am very pleased to tell you that 3D structures were successfully printed today using your material, and with good quality. Your material is definitely processable using our modified FDM technology. And to be honest, it is the most straightforward material I have ever tried in our equipment”

Steve Cooke, Consultant, Orthopaedics

“Using torc material, which can be fully customised on the patient, will revolutionise orthotic care”